De Angeli Prodotti

Every wire, everywhere.

We are located in Bagnoli di Sopra, in the province of Padua.

The company (which has around 400 employees and a turnover in 2023 of around EUR 250 million) is active in the field of electric power cables and conductors, in which it has become a leading player throughout Europe in the course of three decades.

De Angeli Prodotti specialises in the production of power transmission conductors, copper catenary lines for the railway sector, and isolated conductors for the windings of all electrical machines, such as motors, generators and transformers.

Through the processes of wire drawing, rolling, insulation with enamels or special tapes and roping, we produce cables which are essential for the generation, transformation and transmission of energy, which are the basis of our economic and industrial system and very important for the Ecological Transition.

For many years now, the company, thanks to the progressive strengthening of its Technical Department and Research and Development Laboratories, has identified Innovation and Sustainability as the leading threads in the development of new high-tech products and the improvement of production processes, which is pursued through cooperation with important centres of excellence such as the University of Padua.

The whole De Angeli Prodotti product portfolio supports the development and integration of Renewable Energy Electricity Networks and is the core of the new ultra-high efficiency motors in electric cars.

Some products such as the Carbon Fiber-core conductors, used by De Angeli Prodotti to replace the traditional steel wire, are ground-breaking due to their lightness and electrical potential, while other products such as the Transposed Copper Cables are similar to works of art, combining the technology of large 30-metre-high enamelling kilns with the meticulous, almost handcrafted ability of specialised workers.

At the heart of De Angeli Prodotti's organisational model are strong and well distributed fundamental values, Safety as first priority, the creative involvement of the entire team at all levels for Continuous Improvement, and a Code of Conduct based on trust and proxy, which increasingly encourages the generational transition to dynamic and qualified young people, who guarantee the company's future development.

De Angeli Prodotti is currently engaged in an investment plan to support the growth of electric infrastructure and sustainable mobility. In addition, a process is underway to select and train 100 new workers and technicians in order to increase production capacity and develop new digitalised products for the electric Smart Grid of the future as the most innovative conductor: the Smart Conductor.

SMART CONDUCTOR

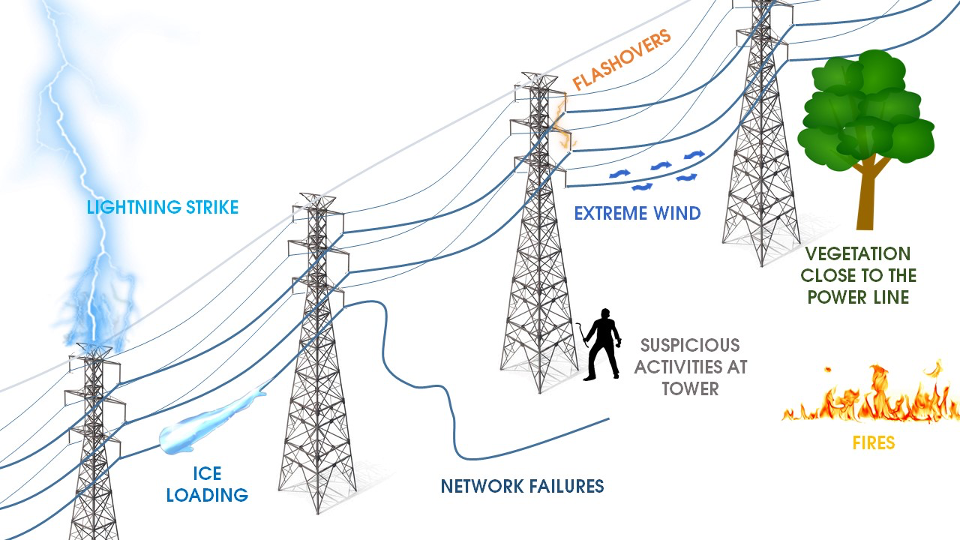

The growing willingness of Utilities to monitor the electricity grids has pushed De Angeli Prodotti to develop and patent an innovative conductor for the overhead power lines with an integrated real-time monitoring system: the Smart Conductor.

Currently the market offers two solutions:

DTR (Dynamic Thermal Rating) with point-by-point sensors;

OPGW (optical ground cable).

The goal of the Smart Conductors is to ensure a continuous and real-time control of the status of the power line, increasing the reliability and efficiency of the system.

All this is possible thanks to the optical fiber integrated in the conductor which are interrogated by an advanced equipment.

It is possible to obtain continuous and real-time information regarding the operating conditions of the line throughout the operating life.

In particular, it is possible to monitor:

- Breakages or failures;

- Temperatures;

- Deformations;

- Vibration and acoustic analysis (future developments).

Advantages

Thanks to Real Time information it is possible to apply targeted and preventive maintenance on the line, reducing (or eliminating!) the possible disservices due to this type of activity.

This type of conductor is fully compatible with existing infrastructures, minimizing upgrade costs as no infrastructure works are required (75% of the total cost of the plant saved). Avoiding the creation of new infrastructures also makes it possible to significantly reduce the environmental and landscape impact as well as the consumption of land as a non-renewable resource.

Advantages for TSOs:

Optimal power flow management;

Reduction of electricity costs;

Reduction of maintenance costs;

Increase the reliability and efficiency of the system.

The Smart Conductors allow REAL-TIME control of the line thanks to the integrated optical fibers.

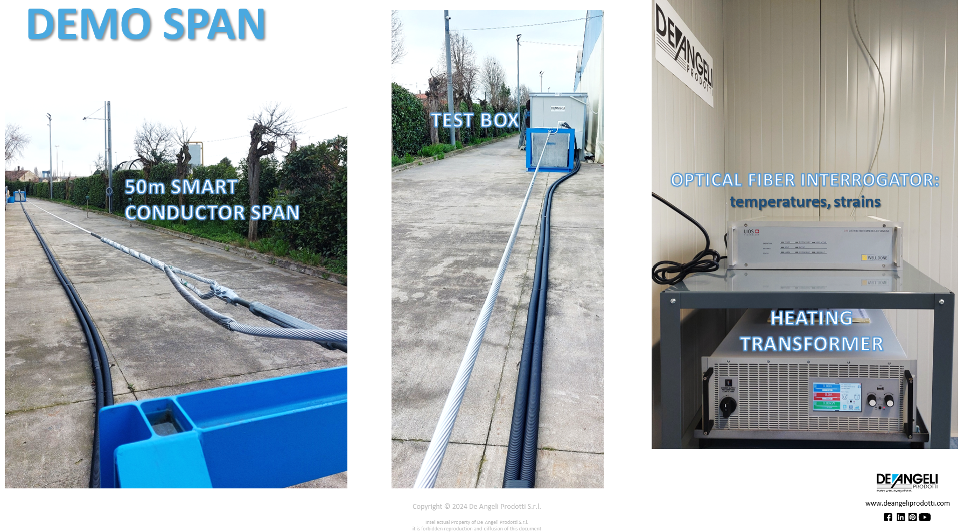

De Angeli Prodotti is proud to invite you all to visit the DEMO Span of the Smart Conductor installed in its facility in Italy to see firsthand the features of this advanced conductor.